Company History

Uteco’s origins: history, technology and the future

Our story begins in 1985, in the hills around Verona, in the industrial area of San Martino Buon Albergo. The idea for the company began with a Veronese entrepreneur who set up his own production unit, an assembly service and an after-sales service, together with four other people who already had experience with flexographic machines. Passion, intuition, growth and a strong motivation towards technological innovation have been in our DNA since the beginning.

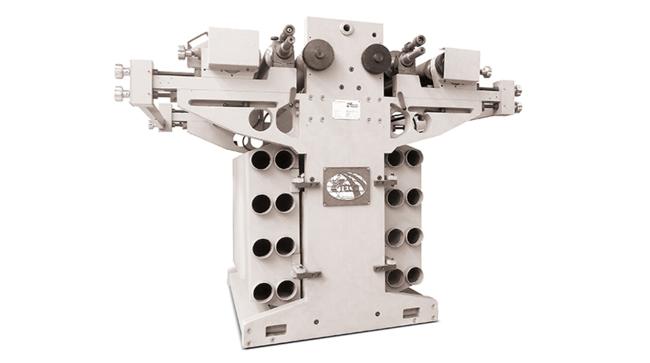

In 1986, Cartenplast placed the order for Uteco’s first two-color stack type flexographic machine: the Bronze, a name that would soon become synonymous with guarantee. The metal which gives the machine its name has, in fact, a very deep cultural significance: it is not only the metal from which one of the medals in sports competitions is made, but it is also the material used in ancient times to craft valuable objects, tools and weapons. It is a light but durable alloy that made it possible to create majestic works that have come to the present day still intact. The two-color Bronze 212 is intended to represent these very values: lightness, excellent quality and stability over time.

In 1992 we created the Jade model, the first innovative, fully automated printing machine, with automated cylinder change. The following year we launched Programm, the first in a rotogravure series.

1997 marked a big turning point as we designed and built the first fully gearless flexographic printing machine for a German customer. With this, we secured our place on the global stage.

In October 2000 we opened our American division, Uteco North America, in Atlanta (GA). In 2002, we manufactured a special rotogravure for a leading English customer operating in the security field. The machine was suitable for de-metallization, printing and registration in one line.

As we settled into the new millennium, our greatest development was our gearless, flexographic machines. Anticipating change in the market, in 2004 we presented at the Drupa fair the Onyx model, the first flexographic printer of the new gearless generation. It soon became the spearhead of our production, which has over 600 machines. Onyx is the natural evolution of the Emerald machine: it elevates its print quality, and, thanks to its extremely easy use and quick job changeover times, it facilitates the interaction between technology and operator. With subsequent evolutions of the Onyx model, we have focussed on the excellence created by a winning product, cementing our position as a world leader in flexography.

To respond to customer demand for flexographic printing machines with high productivity, we started the Diamond HP project, designed for high performance, maximum print quality, reliability and efficiency. The Diamond HP 808 with water-based inks was exhibited at Drupa fair in 2008.

In the same year, we continued to develop special machines, in particular coaters and laminators, introducing two lines: one for converting self-adhesive painted film, and another one for the production of self-adhesive silicone paper.

Also in 2008, we presented the first application of Electron Beam (EB) technology on a flexographic machine. The research on EB technology continued and in 2011, we introduced the Thermilox® patent, which guarantees accurate and continuous control over ink temperature during printing.

2010 was the year that saw us present the first Silver SIL roto-offset machine for the safety sector, built for a major bank by our business unit dedicated to the design of specialist machinary.

The following year we brought out the Crystal line, a dynamic and compact flexographic machine equipped with patented automatic control systems, developed exclusively by our teams: Touch & Go® and Kiss & Go® systems. In 2013 we launched the Diamond VHP, designed for printing and pre-printing on large formats of up to 800 meters.

In 2015 we celebrated our thirty years by presenting two new lines: the compact flexo Onyx XS and the innovative rotogravure Next 450. With our anniversary, we inaugurated a new season of investments addressed to different areas of the company: to the training of human resources, according to the most modern operating methods based on 6Sigma and Lean Production; to the Research and Development department for innovative projects, such as printed electronics applied to Smart-Active Packaging, also in collaboration with Italian and foreign institutions and universities. Finally, we invest in a new Working Center at the headquarters in Colognola, in order to have complete quality control of the machines’ main mechanical components.

In 2018, NB Renaissance acquired 81% of the Uteco Group. In May, we went to the first Print4All conference to present our new products and company’s structure.

We launched our new rotogravure press, NXS 300, the leading machines for short runs and our new solventless lamination machine, Rainbow 4.0, with green technology solutions.

2022 begins with the launch of our new brand identity, a renewed image in the logo, in the colors and in the many communication initiatives, as well as a great variety of international meetings occasions such as the series of events “Flex-on-Road”, where Uteco and the partners bring the world of flex-converting directly to our customers.

The Flex-Converting Alliance, FlexCA, is an Alliance of Companies through binding Equity Agreements to offer best-in-class products to Converting Industry. The widest and unique Portfolio in the Converting Industry, covering Extrusion, Printing & Slitting. Our offerings include: Extrusion with GAP and CMG; Printing and Coating & Laminating with Uteco machines and Smartjet's digital technologies; Vision Systems for Quality Control with Vision; Slitters Rewinder with Bimec.