These machines are the result of a total synergy between our engineering expertise and technological systems, which have already been extensively proven in other fields.

We offer various laminating and coating machines intended for the production of food packaging, products for pharmaceuticals, construction, such as roofing substrate, aluminum-paper laminates for the inside of cigarette packs, and for the production of adhesive tape, adhesive labels. These are machines that can work on different substrates such as film, paper, aluminum, cardboard, PVC.

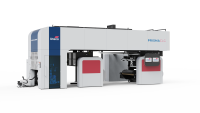

All our laminating machines feature an integrated solvent and solventless or water-based multi-process coating and laminating system. They have a highly flexible design that can be customized by choosing from optional innovative equipment and technologies.

Laminating machines for flexible packaging industry are used to join together different webs creating a single web composed of a multi-layer structure. Laminate coat a glue on a primary material and laminates secondary material onto it. A typical application for flexible packaging are solventless laminators which employ a two-component glue. Dry and wet bond laminators use solvent base or water based glues. in the flexible packaging industry also the so called “combi machine” are common. These employ an interchangeable trolley system which allows different types of coatings or laminations depending on available trolleys. Coatings used in the packaging industry are many and various; in particular, hot and cold seal ones as well as hot melt and wax ones are commonly used.

Source: https://www.tecnoconverting2000.com/en/used-machines/c-3-converting-mac…