Active Pack

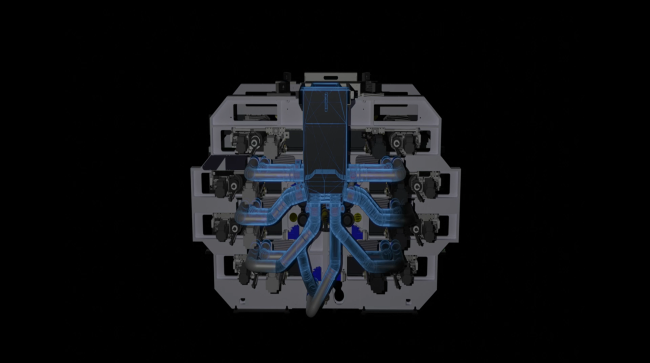

Active Pack focuses on reducing environmental impact that consists of several technologies: Active Start, Active Ink, Active Dry. Active Pack enables savings up to 300k EUR per year for energy consumption and consumable material.

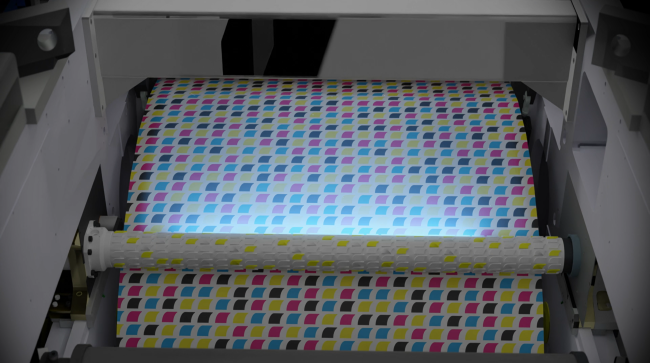

Active Start is the best technology on the market for job startup. With Active Start it takes less than 3 minutes for automatic pressure and register setting, generating less than 8 meters of material waste at each startup.

Active Ink complements Active Pack by allowing pumping cycles to be adjusted according to the printing characteristics identified by Active Start enabling the reduction solvent consumption by up to 40% and energy consumption by up to 60%.

Active Dry carries out the function of optimizing energy consumption in the drying phase. The drying power is adjusted according to the printing characteristics (ink coverage) previously identified by Active Start. Active Dry enables saving up to 50% in energy consumption during drying phase.

The new Active Dry-T also manages to identify the ideal tunnel drying temperature by collecting information derived from the print set-up process, such as substrate type, thickness and width.

Find out how Active Pack can help you save on costs while enhancing your machine's performance.