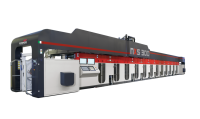

Next 450

High automation and reduced job change times for a new concept of rotogravure printing.

- Rotogravure printing

- Medium and long runs

- Plastic, Paper, Cardboard

- Industrial Films, Paper Bags

Next 450 is the rotogravure printing machine designed to guarantee faster job changeovers and reduce set-up times through automatic solutions. An example: at the end of the job, the cylinders used are automatically ejected and those of the next job are inserted with a semi-automatic trolley system. Next 450 also allows a significant reduction in consumption thanks to the encapsulated inking to eliminate emissions, ink splashes in the printing area, and the energy-saving Cube® ventilation system.

Managing the Next 450 machine is simple and intuitive: it has a single operational control point, with a touchscreen, from which to enter all the print settings and monitor the progress of the parameters during work.

All these features make the Next 450 the ideal machine for medium and long print runs and to print on different types of packaging: flexible food and non-food packaging, drinks, envelopes and bags, labels.

| Material widths (mm) | 1050 - 1350 - 1550 |

| Print repeat (mm) | 450 ÷ 920 |

| Maximum speed (m/min) | 450 |

| Tension range (daN) | 4 ÷ 50 |

| Hoods length (m) | 2,4 |

| Inks | water based, solvent based |

| Reels diameter (mm) | 1000 |

| Dimensions (m) | 32 x 7,5 x 6,8 |

Final applications

Materials

It is the innovative Uteco automatic and modular washing system. It allows you to wash all the color units at the same…

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

Dynamic control of the web tension (with PID controls) to obtain a perfect registration precision and a correct print…