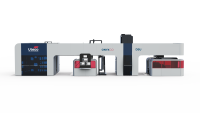

Onyx XS Eco ONE

The compact Onyx machine for ecological flexo printing: ergonomic and efficient, energy saving and with low emissions.

- Flexographic printing

- Short, medium runs

- Label, adhesive label

- Flexibile packaging

Onyx XS Eco ONE, for short and medium runs, besides guaranteeing high-quality printing quality and maximum efficiency, responds to the market’s demand and current legislation to reduce consumption and harmful emissions.

It is equipped with EB3 technology which uses electron beam drying inks in the printing process, obtaining certified and safe products particularly suitable for food packaging with reduced production costs. Together with the printing, it carries out the coating and laminating processes, with instant polymerization thanks to the electron beam technology, and finally the cutting.

The configuration is ergonomic and designed to simplify the operator's work-flow, from cleaning and maintenance to the control of printing processes.

| Mechanical speed (m/min) | 300 |

| Min. print repeat (mm) | 240 / 310 |

| Max. print repeat (mm) | 650 |

| Print widths (mm) | 620 / 1020 |

| Material widths (mm) | 650 / 1050 |

| Inks | water based, solvent based, UV/EB |

| Colors | 8 |

| Tension range (daN) | 2 - 60 |

| Reels diameter (mm) | 800 - 1000 |

| Dimensions (m) | 10 x 4,3 x 5,4 |

Final applications

Materials

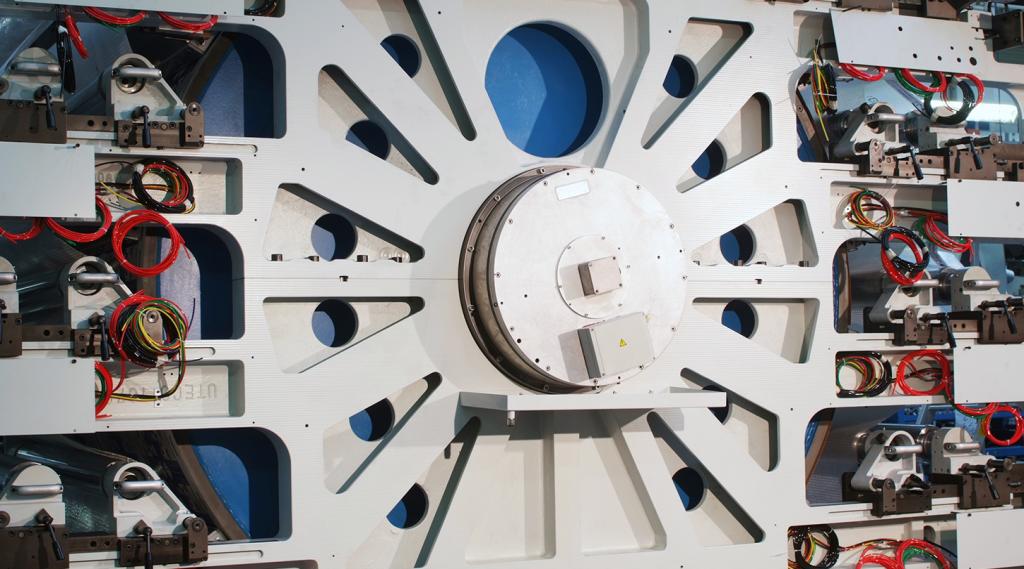

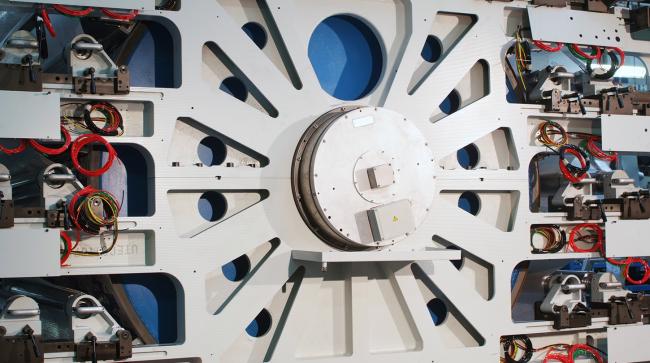

The exclusive direct transmission between the main engine of the machine and the central drum allows to obtain very high…

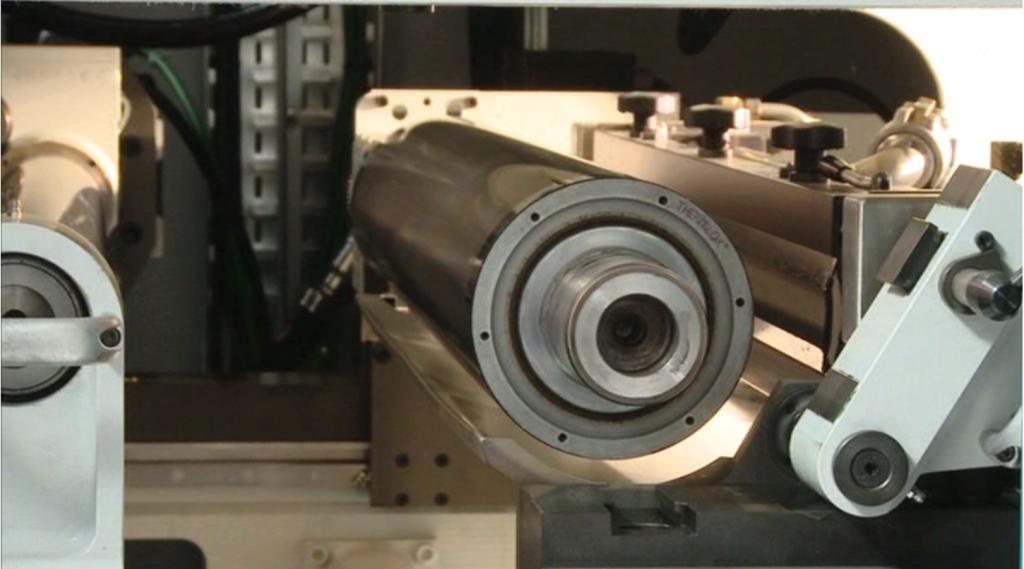

The Uteco patent "Thermilox®" system is applied to flexographic printing that uses UV or EB inks and guarantees accurate…

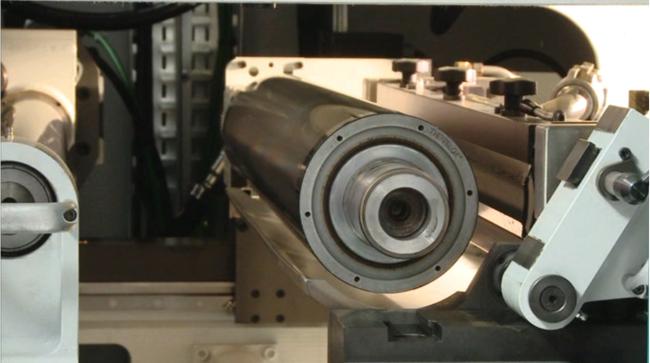

It is the Automatic Adjustment of the Printing Pressures. It allows you to perform color reading and pressure adjustment…

It is the innovative Uteco automatic and modular washing system. It allows you to wash all the color units at the same…

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

Dynamic control of the web tension (with PID controls) to obtain a perfect registration precision and a correct print…