OnyxOMNIA

OnyxOMNIA is the First FlexoDigital Printing Press in the market as best fit for short and medium runs.

OnyxOMNIA combines the best attributes of Flexo and Digital technologies providing the ultimate in technological advance and automation combined with great ease of use for the operator. Technical innovations are taken to the next step by enhancing performances in terms of versatility and sustainability.

Discover OnyxOMNIA uniqueness:

- The most Versatile: OnyxOMNIA can be equipped with 1 or more Down-Stream Units (DSU) for Functional or Embellishment Purposes, printing with all type of substrates and inks type.

- The lowest Operating Costs: balanced usage of Flexo CI units for printing solid colors and Digital Units for printing Process Colors (CMYK). This means fast changeover: instantaneous on Digital and less Flexo Colors to change at each Job changeover.

- The most Productive: up to 400 mpm printing speed with 1300mm web width. OnyxOMNIA is equipped with our Active Start, the best tech for automatic pressure setting and register setting. Up to 33 % Faster Complete Changeover Vs Flexo thanks to combination of Digital and Flexo Technology.

- The most Sustainable: ESG-oriented flexo machine thanks to the innovative Active Pack Technologies, the ultimate techs for energy saving and consumable material reduction. Active Pack enables savings up to 300k EUR per year for energy consumption and consumable material.

- The best Printing Quality: the quality of Flexo Tech for solid Colors (e.g. Metalized Colors) with the Best Flexo printing Quality. The Flexibility of Digital Tech for Variable Data to print details and variable data/graphics.

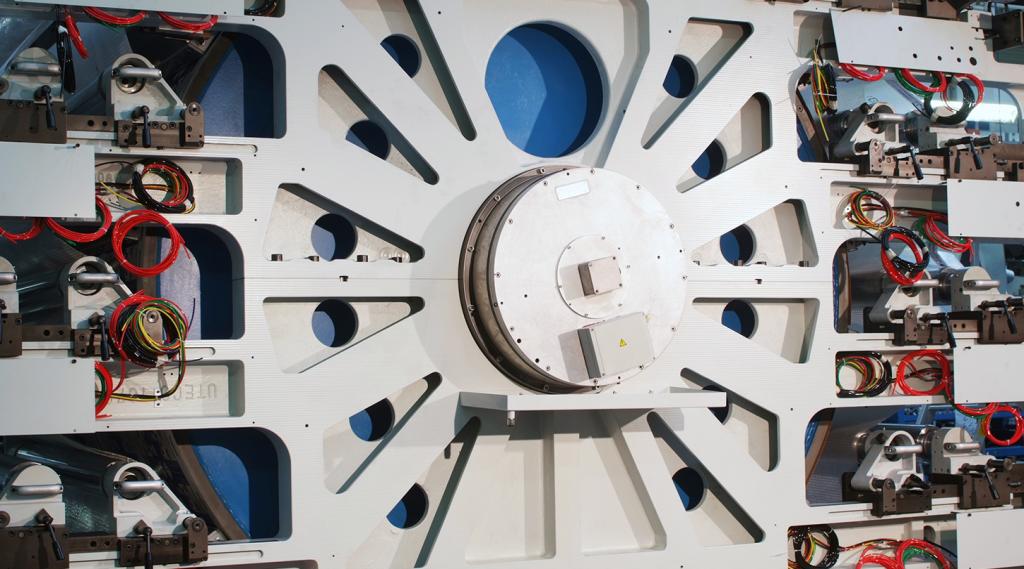

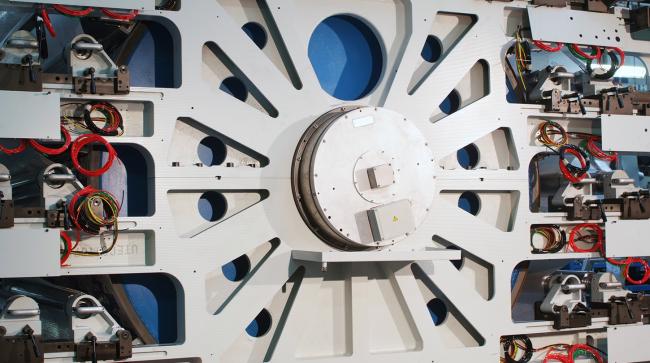

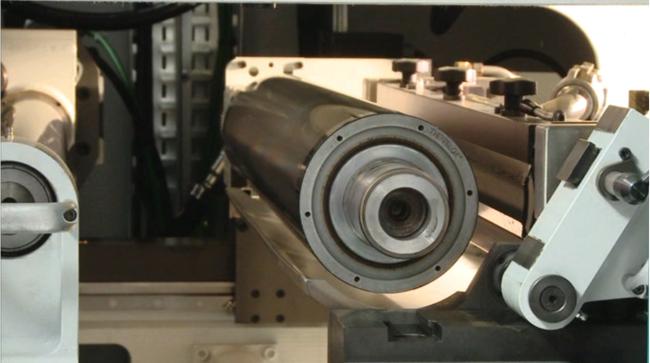

- The most Compact: our new Configuration of Flexo CI Drum + Digital Printing Engine is Patented allowing the Shortest Web Path.

- The most Ergonomic: easy to access printing engine, just 1,5 meter above the ground and easy to maintain and clean. The Most Ergonomic Cockpit in the market thanks to the floating HMI, adapting to operators’ height. Single Integrated Control Panel, controlling both Flexo and Digital Printing Techs from a single spot.

OnyxOMNIA can print with up to 10 Colors + In-line Finishing Units (our DSU) with water/solvent/water + solvent Ink Types.

OnyxOMNIA is the most productive for short and medium runs, with a printing speed of up to 400 m/min and a maximum printing width up to 1320 mm.

ESG-oriented flexo press: OnyxOMNIA's goal for full sustainability focuses on minimizing environmental impact with the Active Pack, which consists of the best technologies in the market for sustainability. Active Pack enables savings up to 300k EUR per year on energy consumption and consumable material.

Equipped with the best technology on the market for job startups: Active Start, which takes less than 3 minutes for automatic pressure and register setting, generating less than 20 meters of material waste at each startup.

The function of optimizing energy consumption in the drying phase is later carried out by the Active Dry® system: the drying power is adjusted according to the printing characteristics (ink coverage) previously identified by Active Start. The Active Dry® enables saving up to 50% in energy consumption during drying phase.

The Active Ink complements the Active Pack by allowing pumping cycles to be adjusted according to the printing characteristics identified by the Active Start enabling the reduction of energy consumption by up to 60%.

The Most Compact on the market for short and medium runs: our New Configuration of CI Drum + Digital Printing Engine is Patented allowing the Shortest Web Path and the Easiest Maintenance & Cleaning Operations.

The Most Versatile, supporting multiple substrate types for a variety of end-use applications. Moreover, the machine can be equipped with different inks’ configurations: water based, Solvent based and Water + Solvent-based.

The new OnyxOMNIA can be configured with the addition of an extensive range of downstream units (DSU) able to sustain different special applications and substrates: our new different types of DSU are equipped with Roto, Flexo and Hybrid Roto+Flexo coating and printing technologies, leading to different types of finishings, such as functional, embellishment, printing and adhesive.

| Max Printing Width | 1320mm |

| Print Repeat Range | 350÷720 |

| Max Printing speed (Flexo/FlexoDigital or Digital) | 400/300 mpm |

| Max Color Units (Flexo + Digital) | 10 |

| Film Tension Range | 2÷40 daN |

| Max Reel Weight | 1100 Kg |

Final applications

Materials

This system allows the preparation of the unused color elements while the machine is printing, seeks a strong reduction…

The exclusive direct transmission between the main engine of the machine and the central drum allows to obtain very high…

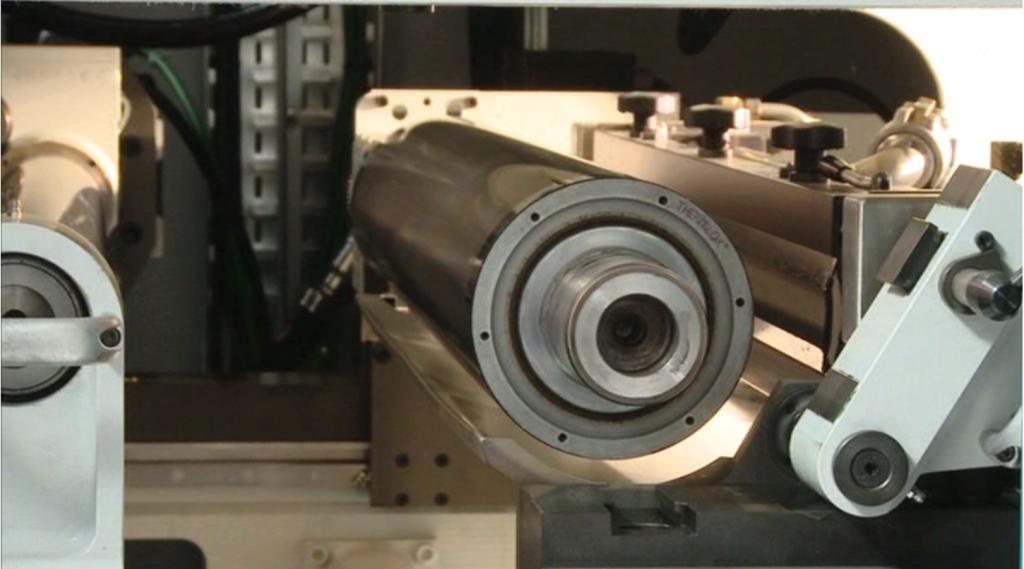

The Uteco patent "Thermilox®" system is applied to flexographic printing that uses UV or EB inks and guarantees accurate…

It is the Automatic Adjustment of the Printing Pressures. It allows you to perform color reading and pressure adjustment…

It is the innovative Uteco automatic and modular washing system. It allows you to wash all the color units at the same…

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

Dynamic control of the web tension (with PID controls) to obtain a perfect registration precision and a correct print…

High speed and extreme efficiency drying system. The advantages are many: high printing speed, low solvent retention…

Add Active Pack to your machine and save more than € 100.000 each year on energy and material consumption. The Active…

No product defined for this product line