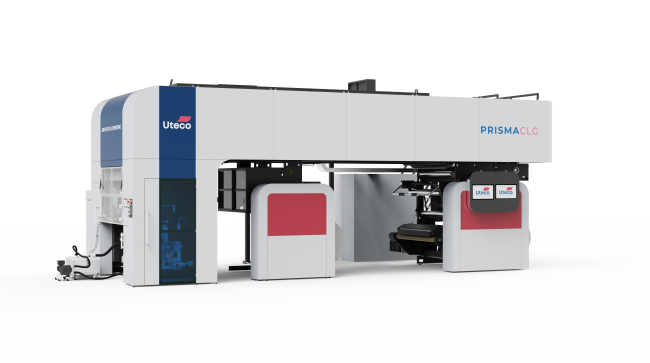

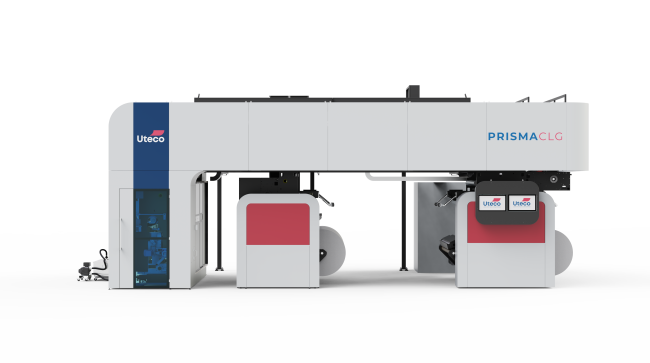

PrismaCLG

Uteco introduces the new PrismaCLG, its state-of-the-art Coating & Laminating machine, designed to enhance productivity and versatility for high quality laminated materials.

The PrismaCLG features a max. process speed of 450 mpm and max. material width of 1550mm.

Experience PrismaCLG great versatility thanks to multiple coating and process types - solvent-based, solventless, and water-based laminating - with all configurations featuring shaftless unwinders and rewinders. The laminating units is available either with 2 or 3 rollers.

PrismaCLG ensures unique benefits for converters:

- High Productivity:

- Fast Changeovers thanks to:

- Dual Web Thread (Optional): the machine is equipped with two web threads, separating solventless and solvent-based laminating processes. This reduces changeover time due to much faster cleaning procedures when changing adhesive type, especially from solventless to solvent-based ones.

- Multi-purpose Trolley: our trolleys can be easily changed for very fast job changeovers and are equipped with automatic washing systems.

- Semi-floating Drying Tunnel (6 meters): our tunnel is equipped with Uteco’s semi-floating technology and special design for nozzles, boosting the drying capacity of the machine.

- Vertical Chamber for Pre-heating: possibility to add a vertical drying chamber before the tunnel for enhanced drying efficiency. This guarantees high precision in temperature control and even more powerful drying.

- Fast Changeovers thanks to:

- Easy and Safe to Operate:

- Operator-Centric Design: PrismaCLG features a fully accessible catwalk making access to the upper part of the machine very easy and safe. This means fast and safe cleaning & maintenance operations.

- Solvent-free environment: A completely new and powerful VOC aspiration system ensures 100% solvent-free environment for the operator.

- Great Versatility:

- Multipurpose Coating Trolley: the machine is equipped with Uteco’s multi-purpose coating trolley that supports Roto, Flexo, Semi-Flexo, and Solventless technologies. It is also equipped with an automatic washing system.

- Duplex & Tandem Configurations: PrismaCLG is available in Duplex and Triplex configurations to meet all types of productivity needs and ergonomic preferences.

- High Automation thanks to Dynamic Tension Technology

The machine is equipped with Uteco’s innovative and automatic Material Tension Control. This technology automatically identifies the correct substrate tension based on the collection of different info, such as substrate type, thickness, width, coating speed and much more. This feature ensures fast setup times and safer operations, supporting the operator in one the most complex phases of the process.

| Max. process speed | 450 mpm |

| Max. material width | 1050, 1350, 1550mm |

| Max. coating width | 1030, 1330, 1530mm |

| Unwin./rewin. max diameter | 1000mm |

| Film Tension | 3÷40 daN |

| Max Reel Weight | 1500kg |

Final applications

Materials

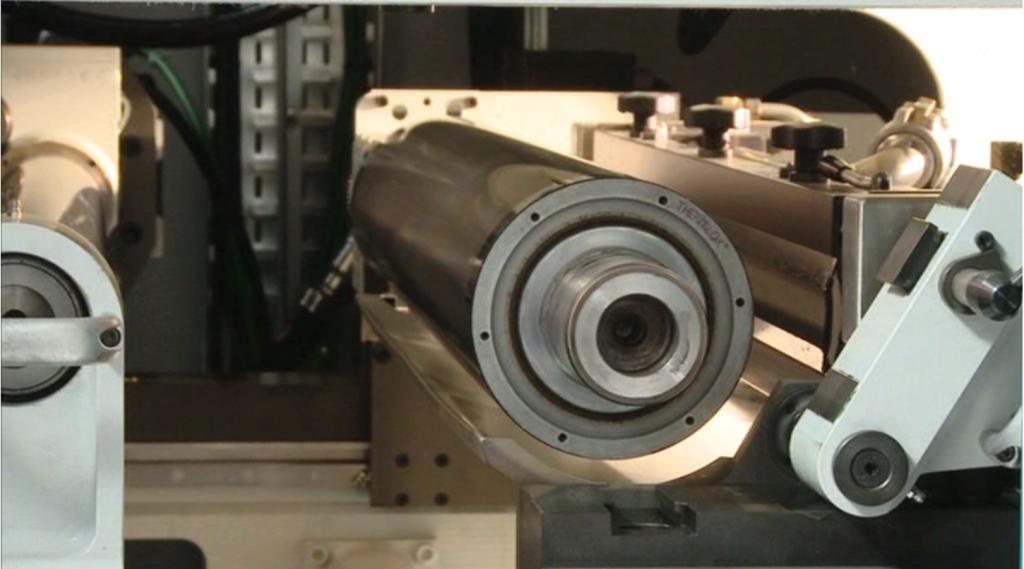

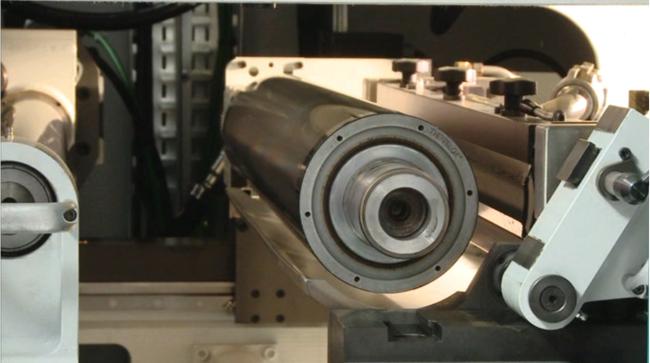

The Uteco patent "Thermilox®" system is applied to flexographic printing that uses UV or EB inks and guarantees accurate…

It is the innovative Uteco automatic and modular washing system. It allows you to wash all the color units at the same…