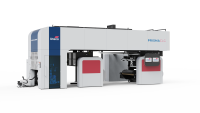

Mistral

Multiple laminating processes in a machine suitable for laminates working on a wide range of materials.

- Laminating and coating

- Short, medium and large runs

- Film, paper and aluminium

- Food & liquid packaging

Mistral is equipped with innovative technologies to work on a wide range of materials: pe, pp, opp, bopp/met, pet, aluminum foils, paper, pvc, nylon.

Mistral consists of two separated coating units, one for solventless adhesive and one for water and solvent based adhesive, that allow the reduction of job change time. A single machine includes different types of coating: solvent-based, water-based, solvent-less, in primer register and lacquering.

The standard equipment can be integrated with the in line cutting unit and additional flexo and roto printing stations.

| Max/Min material width (mm) | 750 ÷ 1550 |

| Max coating width (mm) | 1500 |

| Min coating width (mm) | 730 |

| Max coating speed (m/min) | 500 |

| Unwid./rewin. max diameter (mm) | 1000 |

| Unwinder tension (daN) | 2 ÷ 40 |

| Rewinder tension (daN) | 4 ÷ 50 |

| Max reel weight (kg) | 1500 |

| Min. size (m) | 13,8 x 3,7 x 6,1 |

Final applications

Materials

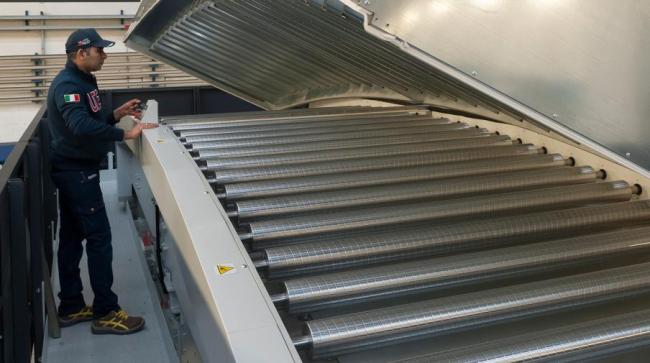

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

High speed and extreme efficiency drying system. The advantages are many: high printing speed, low solvent retention…