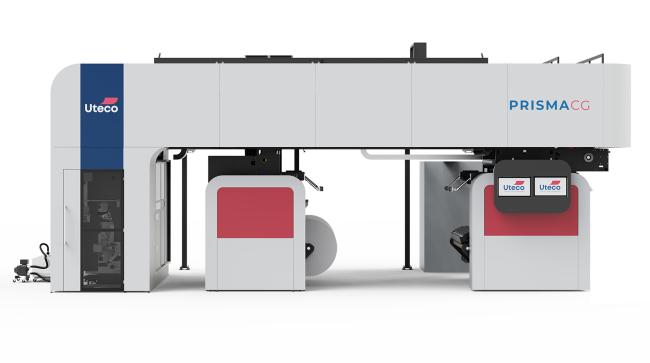

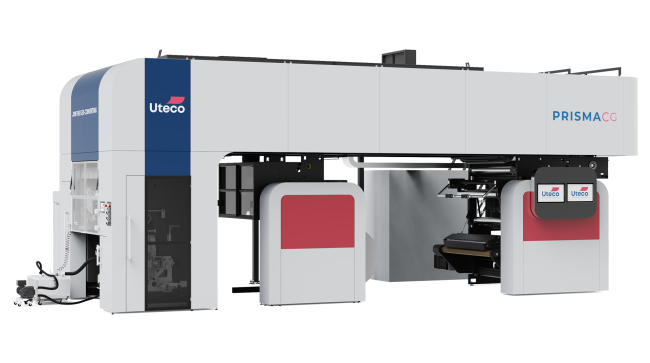

PrismaCG

Uteco presents the new PrismaCG, a cutting-edge coating machine engineered to boost both productivity and flexibility in the production of high-quality coated materials.

With a maximum process speed of 450 m/min and a maximum material width of 1550 mm, PrismaCG delivers top performance across a wide range of applications.

Designed for maximum versatility, it supports various coating processes – including solvent-based and water-based – and comes equipped with shaftless unwinders and rewinders in all configurations.

PrismaCG ensures unique benefits for converters:

-

High Productivity

PrismaCG is built for fast-paced production, delivering exceptional efficiency through innovative design features.- Fast Job Changeovers:thanks to Uteco’s Multi-purpose Trolley, job changes are quick and seamless. Each trolley is designed for easy replacement and comes with an automatic washing system for minimal downtime.

- Enhanced Drying Efficiency: the 6-meter Semi-Floating Drying Tunnel, featuring Uteco’s advanced nozzle system and semi-floating technology, significantly boosts drying performance.

- Optional Vertical Pre-Heating Chamber: add-on vertical drying before the tunnel provides even more powerful and controlled drying, with precise temperature management for demanding applications.

-

User-Friendly and Safe Operation

PrismaCG puts the operator first with features that prioritize usability and workplace safety.- Operator-Centric Access: the machine includes a fully accessible catwalk, making it easy and safe to reach the upper areas for cleaning and maintenance.

- 100% Solvent-Free Working Environment: A newly developed VOC aspiration system ensures a completely solvent-free environment, enhancing safety and comfort for operators.

-

Superior Flexibility

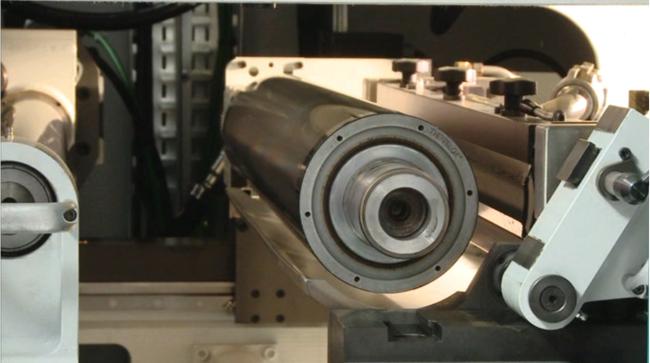

Designed to adapt to a wide range of production needs, PrismaCG offers outstanding versatility.- Multipurpose Coating Trolley: compatible with Rotogravure, Flexo, and Semi-Flexo technologies, this trolley is also equipped with an automatic washing system for hassle-free transitions.

- Multipurpose Coating Trolley: compatible with Rotogravure, Flexo, and Semi-Flexo technologies, this trolley is also equipped with an automatic washing system for hassle-free transitions.

-

Advanced Automation with Dynamic Tension Technology

Uteco’s cutting-edge Material Tension Control system takes automation to the next level:- Automatically adjusts substrate tension by analyzing parameters such as material type, thickness, width, and coating speed.

- Reduces setup time and minimizes human error.

- Enhances safety and simplifies one of the most complex phases of the process.

| Max. process speed | 450 mpm |

| Max. material width | 1050, 1350, 1550mm |

| Max. coating width | 1030, 1330, 1530mm |

| Unwin./rewin. max diameter | 1000mm |

| Film Tension | 3÷40 daN |

| Max Reel Weight | 1500kg |

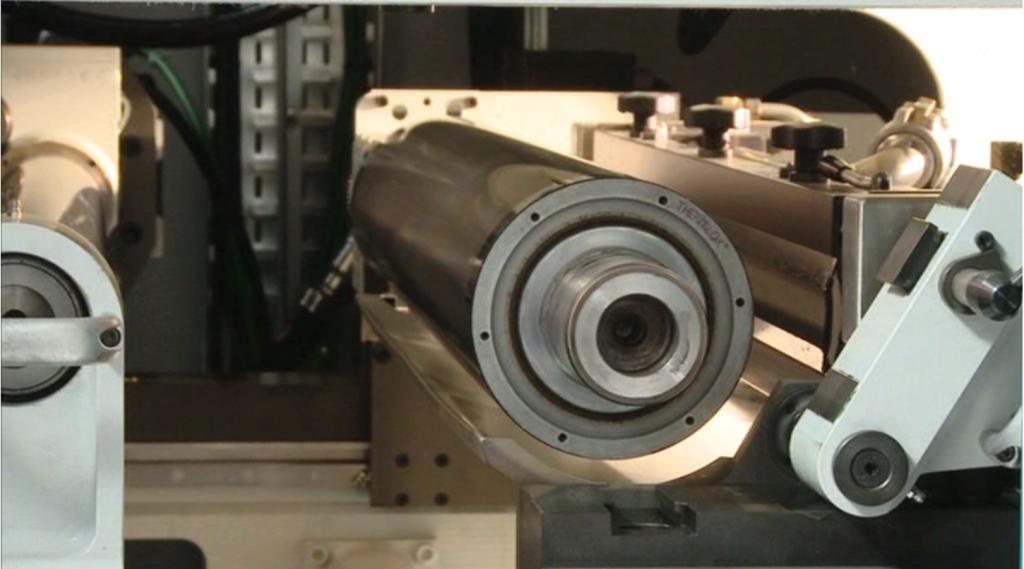

The Uteco patent "Thermilox®" system is applied to flexographic printing that uses UV or EB inks and guarantees accurate…

It is the innovative Uteco automatic and modular washing system. It allows you to wash all the color units at the same…

No product defined for this product line