In our Innovation Lab, always looking at the future, we lead pioneering studies on new printing technologies and sustainable materials, also thanks to the cooperation with main partners in the world of testing and development of ever-innovative solutions.

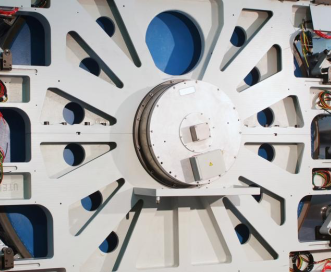

Inside the Converdrome® we have Uteco’s Demo Center: in this space dedicated to innovation we do machine testing, as well as live print tests and demonstrations. We develop real time solutions for customers to improve the machine operation and optimize the processes before the final delivery.

We promote scientific and technological research in order to realize highly automated and safe machines and processes, also respectful of the environment, of the customers’ safety and of the operators’ health.

Highly skilled specialists and researchers work in our Innovation Center, ConverDrome®, to design new technologies aimed at making our machines ever more efficient. We are able to develop new processes and applications thanks to the high levels of efficiency and performance of our machines.

You can see our complete approach to solutions in the products we make, allowing you to see how we innovate according to our customers’ requirements.

We are thousands of miles away but very close in our way of thinking. I chose Uteco because it has an innovative vision, and its printing machines are perfect products from every point of view.

RYOSUKE SAITO

Managing Director and Owner at Daishowa Paper Products

We believe that investing in new technologies is important to offer our customers innovative and advanced solutions, without overlooking the respect for the environment. For this reason, we rely on Uteco solutions for flexo and rotogravure printing, which are excellent and environmentally friendly at the same time.

RENATO LUSA,

CEO at Renato Lusa S.r.l.

Our collaboration with Uteco has driven the Central American market to a high level of technology, filling the previous gap between European and North American markets. Thanks to this partnership, we have become the reference supplier for the packaging industry in Central America and in the rest of Latin America.

RIGOBERTO SOTO,

Production Manager at Empaques Universal

In order to satisfy our customer base, we need to plan continuous investments in the most advanced production technologies, as well as in the training of our staff. We know and trust Uteco and their local agent, Sareltech, so investing in a third Uteco machine was a natural decision. We want to deliver high quality print and thanks to the Onyx 808 we can reach these standards.

ROGAN ROBERTSON,

Managing Director at DBC Plastics