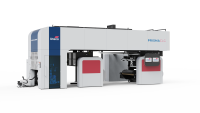

Mistral MV

The coating and laminating machine optimal for printing in register matte varnish and for solventless lamination: two integrated process ensuring efficiency and cost saving.

- Laminating and coating

- Short, medium and large runs

- Film, paper and aluminium

- Food & liquid packaging

Mistral MV is the optimal laminator to print in register matte varnish and for solventless lamination.

The integration of these two processes is the main advantage of this machine, with high efficiency at low investment cost and short amortization timings.

The configuration consists of a flexo unit positioned between the rewinder and unwinder, for the printing of a matte or sparkling varnish, in register with the preprinted substrate. This flexo unit is equipped with the Uteco technology UDD®, that gives the sparkling, matte and satin effects.

It also counts a drying tunnel, for fast varnish drying, a secondary rewinder and the solventless laminating process.

This machine can be integrated with a corona treatment for the primary and secondary film, in line cutting unit and other options, including the Uteco patented job changeover systems.

| Max/Min material width (mm) | 1050 ÷ 1550 |

| Max coating width (mm) | 1500 |

| Min coating width (mm) | 730 |

| Max coating speed (m/min) | 400 |

| Unwid./rewin. max diameter (mm) | 1000 |

| Unwinder tension (daN) | 2 ÷ 40 |

| Rewinder tension (daN) | 4 ÷ 50 |

| Max reel weight (kg) | 1500 |

| Min. size (m) | 14,5 x 4,5 x 5,8 |

Final applications

Materials

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

High speed and extreme efficiency drying system. The advantages are many: high printing speed, low solvent retention…