OnyxGO

OnyxGO continues the long-lasting success story of Uteco’s Onyx flexo presses.

The newly designed OnyxGO is the best CI flexo press for short runs, ever!

The press is equipped with state-of-the-art technology to guarantee excellent printing quality, maximum ease of use for the operator and fastest changeovers in the market.

- New Iconic and Robust Design

- The Most Productive for ultra-short and short runs thanks to fastest changeover in the market

- The Most Sustainable and efficient thanks to Active Pack, the revolutionary energy and material saving system that allows you to get back 100% of the cost of the OnyxGO over time!

- The Most Compact in the market: total footprint of less than 50 sqm with minimized operating space

- The Easiest and Safest to Operate: designed for operators’ maximum ergonomics

- The Most Versatile: fit all materials and inks type requested by the flexible packaging market

OnyxGO is the fastest CI press in its market segment and is available in two configurations: 8 and 10 colors, both with a maximum printing width of 1320mm and maximum print repeat of 760mm.

DESIGNED WITH PURPOSE

The new design of our OnyxGO defines a strong and recognizable identity. Moreover, it provides a sense of order and compactness while the new shape conveys efficiency and care in terms of use and interaction.

THE MOST PRODUCTIVE FOR SHORT RUNS

The press runs at incredible high speed of 400 mpm and is equipped with state-of-the-art technology for the fastest changeover: automatic impression setting and instantaneous register setting in less than 3 minutes. This new technology, our Active Start, reduce the material waste at each startup to less than 8m and increases production uptime.

THE MOST SUSTAINABLE

Eco-friendly, efficient and built to last: with Active Pack, our flexographic press pays for itself, day after day.

Our innovative solution brings together three cutting-edge technologies that revolutionize the way we print: Active Start, Active Ink and Active Dry®. With Active Pack, you can save up to 50% on energy consumption and reduce material waste by up to 30%. And that's not all: the savings achieved will allow you to get back the cost of the machine in just a few years of use!

In addition to the new technologies contained within Active Pack, Dynamic Doctoring® ensures optimized ink flow and constant pressure within the doctoring chamber: ink volumes are minimized ensuring savings in consumption.

Sprint Wash technology ensures very fast wash cycles: less than 3 minutes for a complete cycle and up to 40% savings in solvent consumption.

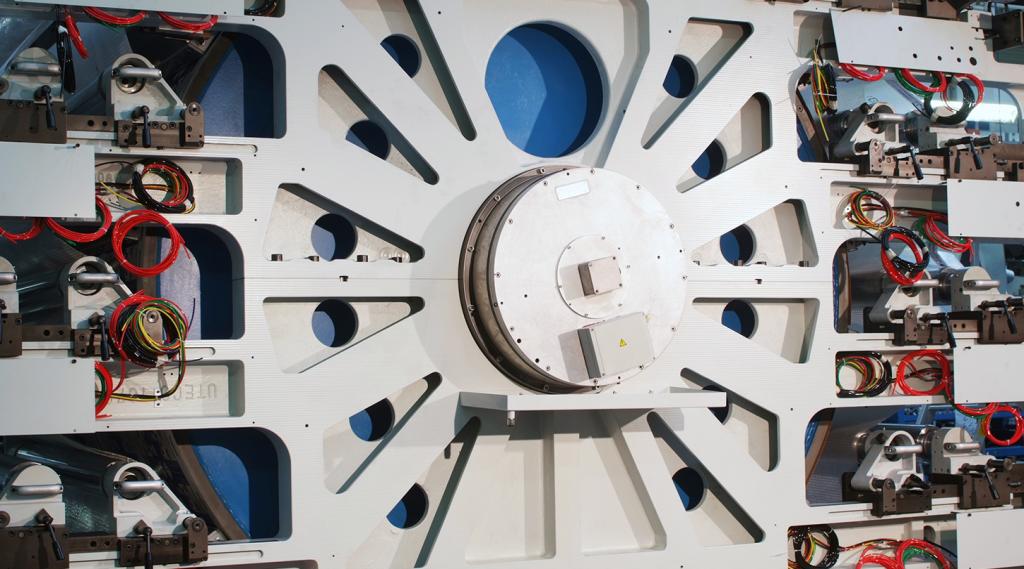

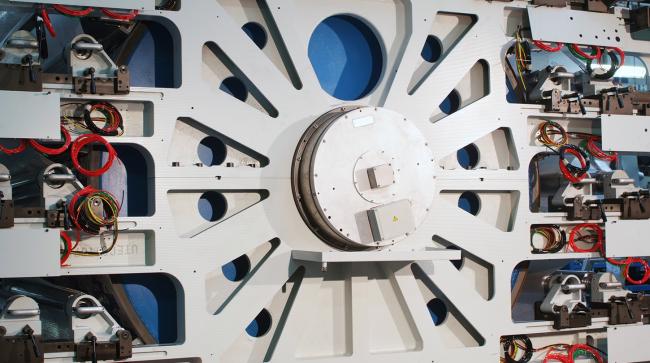

THE MOST COMPACT

OnyxGO is the most compact in its market segment with a total footprint less than 50 sqm. The new positioning of the Washing and Inking System on the side of the CI Drum frees up the space on the back of the machine.

THE EASIEST AND SAFEST TO OPERATE

OnyxGO is the most user-oriented machine in the market, thanks to new features for operators’ greatest ergonomics:

- Inter-color Dynamic Drying Boxes are fully removable to guarantee easy access to CI Drum while nozzles can be easily substituted to enhance drying power

- Dynamic Cockpit is the symbol of personalized ergonomics: the Most Ergonomic Cockpit in the market thanks to the floating HMI

- Dynamic Lift is our integrated lift within the CI Unit to reach the higher printing units easily and safely

- The Upper Part of the Machine is fully accessible by means of a Catwalk, extended to the total length of the machine

- The Innovative Machine Casing is designed to contain noises: the resulting noise level is less than 80db

| Printing Width Range (mm) | 820 - 1020 - 1320 |

| Print Repeat Range (mm) | 260 ÷ 760 |

| Max printing speed (mpm) | 400 |

| Color Units | 8 o 10 |

| Film tension (daN) | 2 - 40 |

| Max Reel Weight (Kg) | 1100 |

Final applications

Materials

This system allows the preparation of the unused color elements while the machine is printing, seeks a strong reduction…

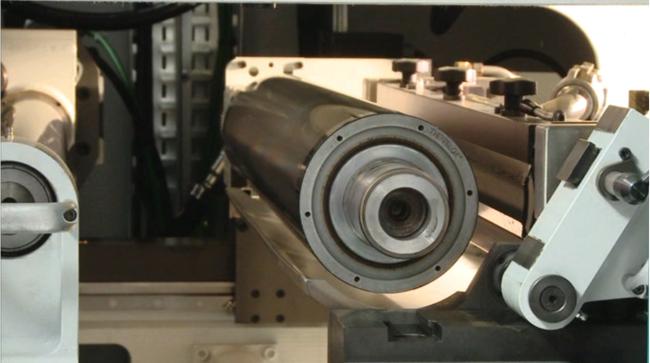

The exclusive direct transmission between the main engine of the machine and the central drum allows to obtain very high…

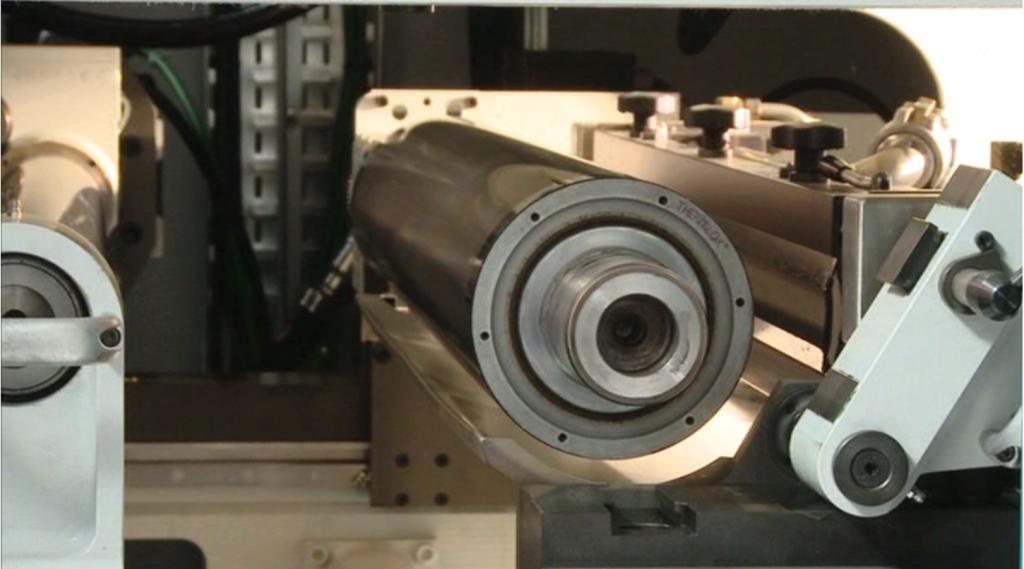

The Uteco patent "Thermilox®" system is applied to flexographic printing that uses UV or EB inks and guarantees accurate…

It is the Automatic Adjustment of the Printing Pressures. It allows you to perform color reading and pressure adjustment…

It is the innovative Uteco automatic and modular washing system. It allows you to wash all the color units at the same…

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

Dynamic control of the web tension (with PID controls) to obtain a perfect registration precision and a correct print…

High speed and extreme efficiency drying system. The advantages are many: high printing speed, low solvent retention…

Add Active Pack to your machine and save more than € 100.000 each year on energy and material consumption. The Active…