Levante

Levante is the new cutting-edge extrusion coating machine by Uteco, powered by Gap technology. Levante represents the pinnacle of innovation, redefining the standards in the extrusion coating industry.

The machine is equipped with state-of-art technology for robustness over time, combining Uteco's proven experience in Converting and Gap's excellence in the Extrusion industry.

Uteco provides a unique end-to-end solution with integrated automation and high value-added technological elements to bond unparalleled laminated material quality. Levante has unique characteristics:

- Exceptional working speed up to 750 mpm, thanks to its robust technology and very efficient semi-floating drying tunnels

- Excellent ergonomic controls with up to three different HMIs, all managed by the same software. Ergonomics and safety features guarantee excellent machine control, maintenance and cleaning

- Top ESG performance guaranteed by Levante's maximum efficiency, featuring an innovative air recirculation system with 100% fume recovery

- Advanced Automation, reducing the need for human intervention

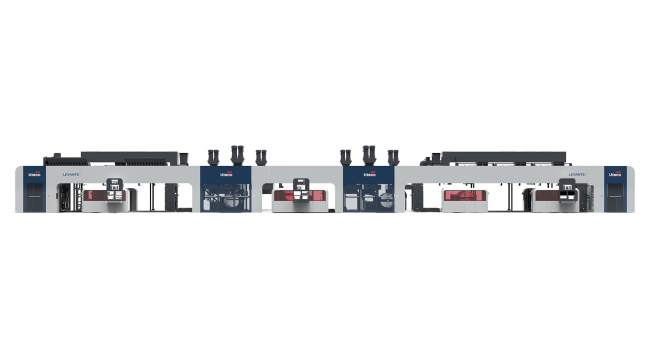

Levante is the innovative extrusion coating machine in the converting industry and it is available in three configurations: Duplex, Triplex (Tandem) and special application Liquid Packaging. Levante has a maximum print width of 2500 mm and a maximum working speed of 750 mpm for the Duplex and Triplex configurations, while the LqP application can reach max 600 mpm.

HIGH EXTRUSION QUALITY

Levante integrates cutting-edge technological components to enhance the quality of laminated materials:

- Precise control over substrate positioning and melt temperatures.

- Meticulously designed screw that optimizes polymer mixing quality for superior results.

HIGHLY PRODUCTIVE

Levante has a high production capacity and guarantees exceptional performances: up to 750 mpm max working speed and up to 2500mm max width. Levante's productivity meets Uteco's know-how with very efficient drying tunnels, equipped with our semi-floating technology that enables primer drying effectiveness.

THE EASIEST AND SAFEST TO OPERATE

Levante has several new features that influence the ergonomic quality of the machine:

- Full machine control with up to three HMI’s managing the machine from different points with the same software

- Fast Changeover of Pressure Roll for Cleaning & Maintenance in < 1 min

- Possibility to use full or partial Teflon Sleeves over Teflon Tapes ensures easier assembly, minimized downtime, enhanced durability of sleeves, and improved lamination quality. Its design prevents sleeves' edge damage, making it a superior choice for seamless operations and higher-quality outcomes.

- Automatic Cleaning System for Chill Roll cleans the roll without the need to remove it from its position. The entire system can be operated and controlled directly from the operator panel/HMI for convenient and efficient operations while limiting downtime.

- Enclosed cabins ensure a safe operational environment by reducing both temperature and noise levels. This setup prioritizes operator safety and comfort while maintaining a controlled, solvent-free atmosphere for enhanced working conditions.

ESG ORIENTED

Eco-friendly, efficient and built to last: Levante is equipped with energy saving technologies such as our air recirculation system. Moreover, the machine guarantees solvent-free environment for the operator and noise reduction.

HIGHLY AUTOMATED

- Automated functionalities include the seamless and automatic adjustment of the pressing unit rolls without manual intervention.

- Incorporates dynamic zig-zag movements to effortlessly restore and maintain the extrusion die optimal position, enhancing operational efficiency.

GREAT ROBUSTNESS

Levante is the outcome of perfect integration between Converting & Extrusion technologies. Uteco is your single partner for end-to-end delivery of converting and extrusion solutions.

| Max Material Width | 2500 mm |

| Max Working Speed | 750 mpm |

| Max Extruder Diameter | 160 mm |

| Max Chill Roll Diameter | 1100 mm |

| Max Material Width | 2500 mm |

| Max Working Speed | 600 mpm |

| Max Extruder Diameter | 160 mm |

| Max Chill Roll Diameter | 1100 mm |

Final applications

Materials

It is the innovative automatic robotic system that allows the automatic transport of the printed reels and the…

High speed and extreme efficiency drying system. The advantages are many: high printing speed, low solvent retention…

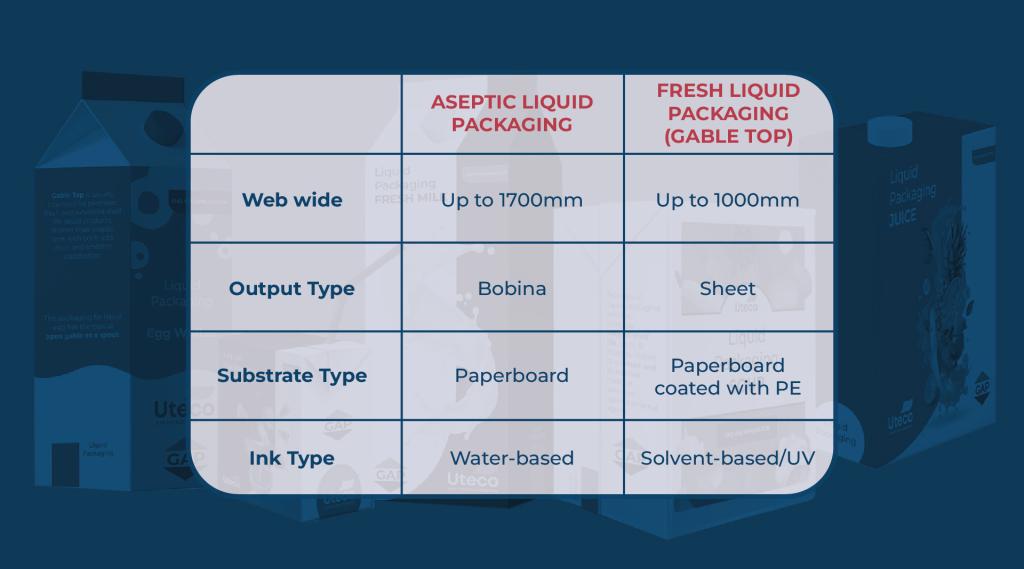

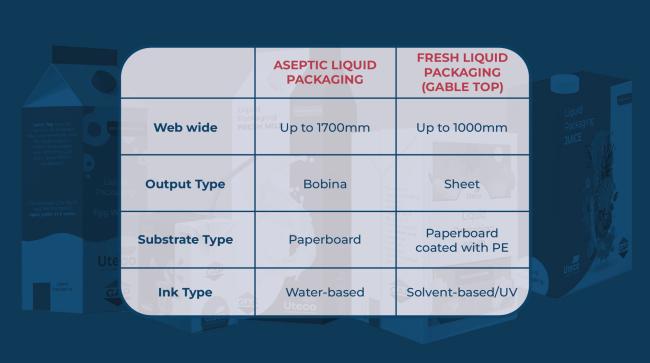

Fresh liquid packaging (Gable top) Uteco has great capabilities across the converting process for manufacturing the…

No product defined for this product line